Binder clips are a great way to keep your edges of your projects firmly pressed together while the glue dries. In fact it’s imperative if you’re wanting your edges to look good after the burnishing process. The problem is that sometimes binder clips leave an unwanted impression on the leather (especially if it’s a firmer leather). No need to sweat it though, there’s an easy fix:

What you’ll need:

Binder Clips

Contact Cement

Leather

(If you’re not sure where to get that, check out this part of the beginners guide).

1. You’ll need to cut two 5/8” x 1” squares for every binder clip you want to pad. I’m going to be making ten, so I’ll be cutting out twenty squares from some scrap leather I have laying around.

The leather I am using is 5oz. 8oz is absolutely too thick for something like this, but you could use anything between 3-5oz and it would still work well.

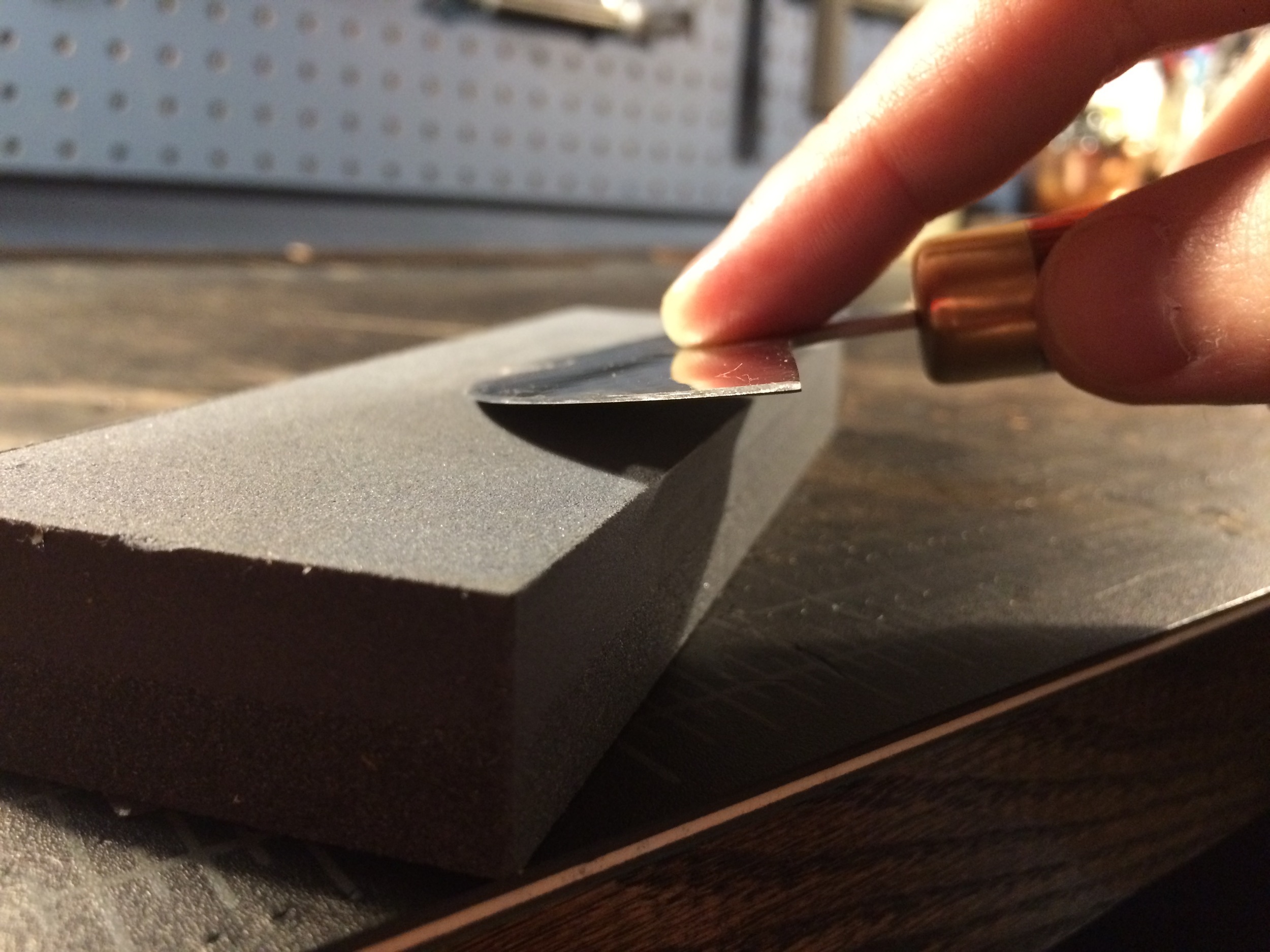

2. Now it's time to wet form the pieces of leather. Wet forming lets you shape the leather how ever you want and it's a super easy process. To do so, I soaked each of the pieces in a bowl of water. Once soaked through, I used a binder clip to bend it in half and set it aside to dry. Once the piece dried I removed the binder clip and the leather stays in this bent position. I wet form like this so the leather doesn't pull away from the clip once it's glued.

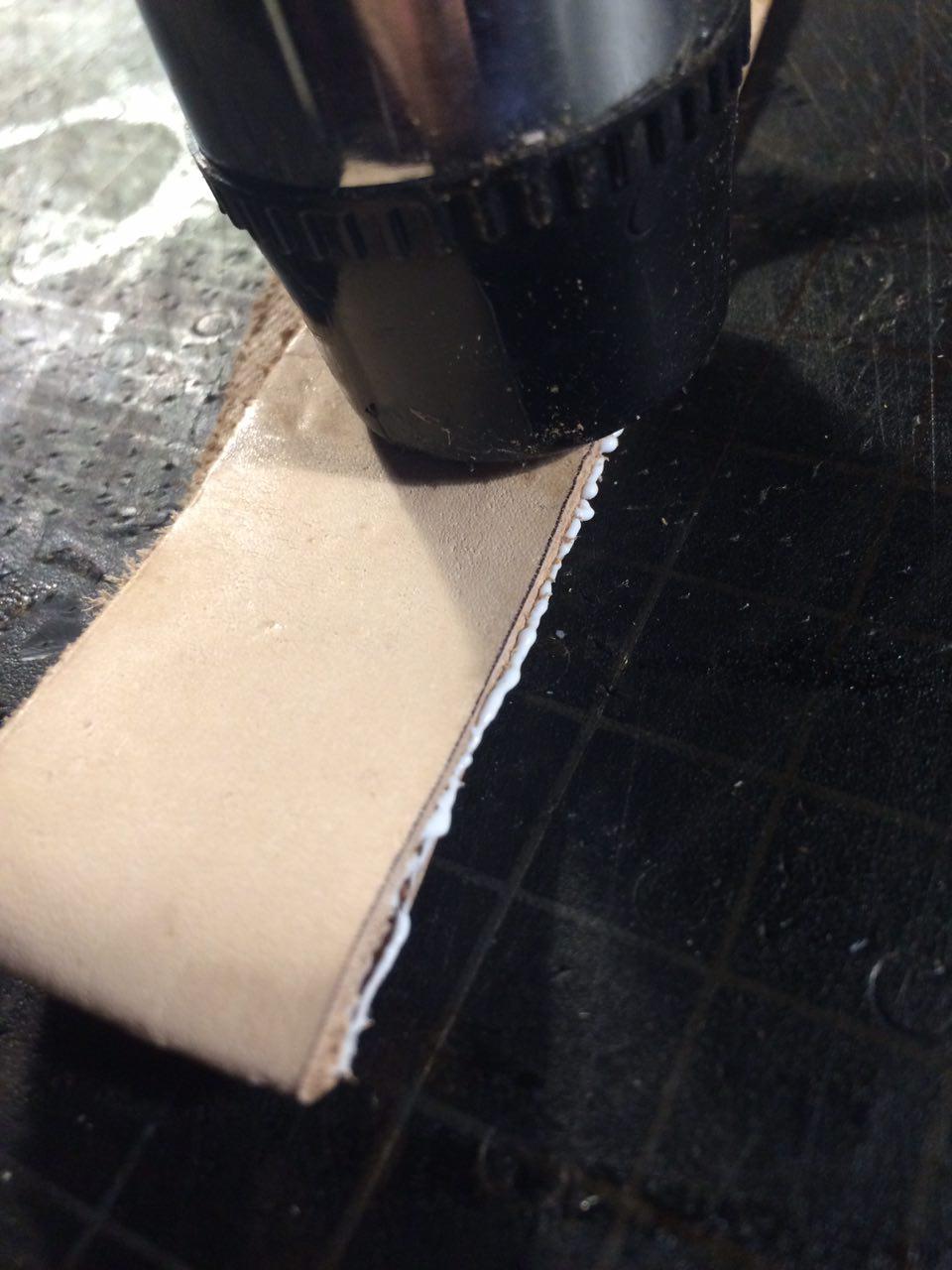

3. After wet forming each piece, I glued the back of the squares and placed them aside to dry. I then glued the binder clips and set them aside as well. This is how contact cement works: you glue two pieces separately, allow to dry, and then place together and apply pressure.

4. Once the glue had dried on both the binder clips and the leather pads, I placed two pieces of leather the around the lip of the binder clip, with an equal amount of leather on either side. I then used two other binder clips to hold the leather pieces in place.

After the glue had time to adhere, they're ready to go. Like I said, an easy fix. I’ve yet to find something more simple, quick, or easy as this solution, but I know they might be out there. If you have a different way to keep your edges together as the glue dries, it’d be great to have you share it with me in the comments below.

Step 1

Step 2

Step 3

Step 3

Step 4

Done!